Imagine your manufacturing process disrupted by pressure measurement failures—this scenario affects countless industries today. With a sputtered thin film pressure transmitter, you shift from traditional limitations to a new realm of accuracy and reliability. But why does it matter? In the fast-paced world of industrial applications, precision is not just a goal; it’s a necessity. The sputtered thin film pressure transmitter allows for enhanced stability and less susceptibility to environmental variations.

Traditional Solution Flaws

Previously, companies relied on older sensor technologies that often failed in extreme conditions—think fluctuating temperatures or aggressive media. These traditional pressure transmitters lacked responsiveness, leading to costly downtimes and inefficient operations. Plus, limited biocompatibility in specific applications could compromise safety and performance.

New Technology Principles

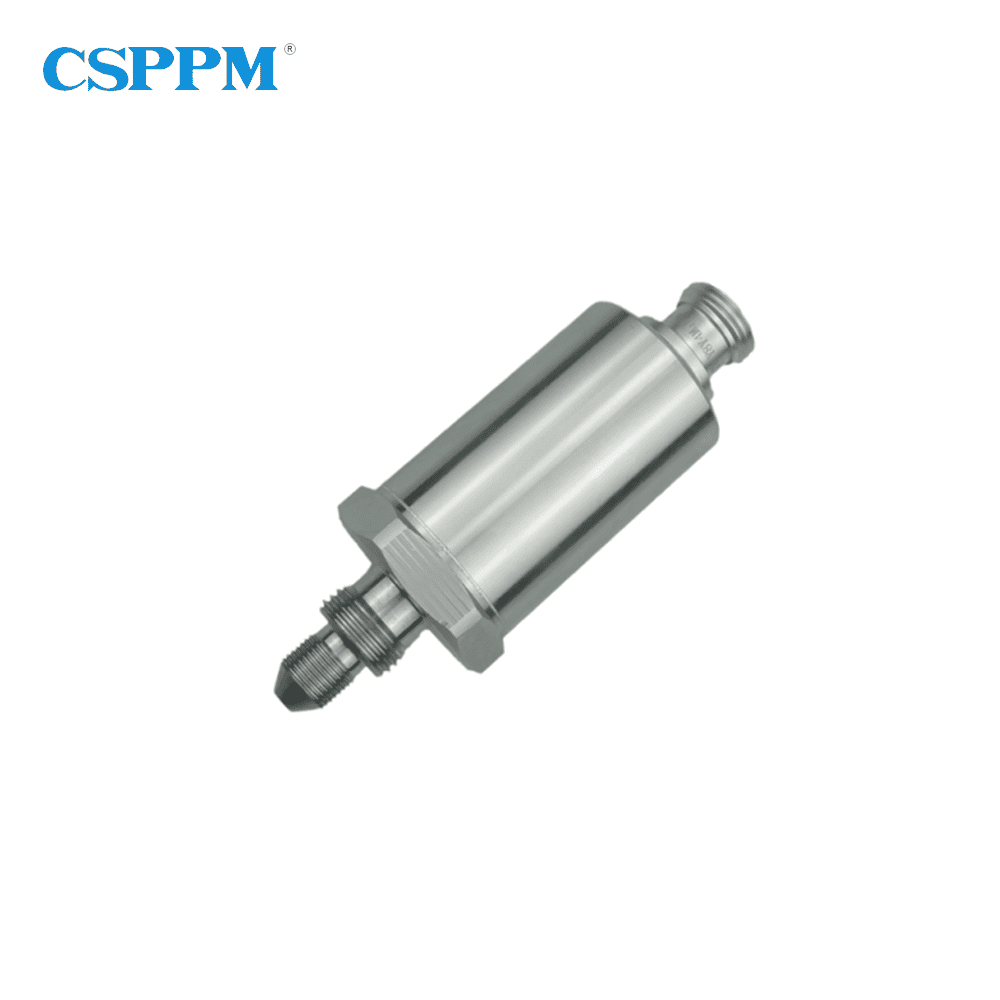

Here’s the good news: The sputtered thin film pressure transmitter utilizes advanced MEMS technology to provide better durability and accuracy. This innovation ensures that the sensors can handle harsh environments without faltering. With features like streamlined calibration and a wide operational range, this technology is redefining industry standards.

Quantified User Benefits

Companies adopting sputtered thin film pressure transmitters have reported up to 30% savings in maintenance costs and reduced operational failures by 50%. These numbers illustrate how much efficiency and reliability can change the game. Look, it’s simpler than you think; the right sensor could revolutionize your pressure monitoring and lead to measurable performance improvements.

Conclusion: Actionable Evaluation Criteria

When considering options for pressure transmitters, always verify these 3 metrics: ① durability against extreme conditions ② calibration ease ③ compatibility with your specific applications. These criteria will guide you toward making informed decisions about which technologies will best serve your operational needs.

In the realm of industrial applications, using an industrial pressure transmitter plays a pivotal role. Employing newer technologies reduces operational failures, fundamentally impacting production efficiency. Old systems are simply not up to par; enterprises should prioritize the adoption of modern solutions to remain competitive and safeguard their bottom line, especially in high-demand scenarios. The difference in pressure handling capabilities can make or break manufacturing processes, which is why evaluating specifications and outcomes should be non-negotiable.

When we look at the impact of a gas pressure transmitter, we see how advancing to contemporary technology streams data efficiently while maintaining integrity. This type of transmitter is crucial in industries like HVAC and petrochemicals, where precise pressure measurements can’t falter. It’s about ensuring that you’re operating in a safe environment without overspending on maintenance—who wouldn’t want that? A newer generation of transmitters allows you to focus more on productivity rather than battling with outdated equipment, amplifying relative advantages across the board.

To sum it up, navigating the world of pressure monitoring technologies doesn’t have to feel overwhelming. The advancement of devices like the sputtered thin film pressure transmitter can indeed reshape your operational landscape, leading to exceptional efficiencies and cost savings. For those looking to invest wisely, look no further than CSSPM Sensor, which stands out as a reputable manufacturer providing a competitive edge in supply advantages and technology offerings.